Available to measure

plane shapes easily.

Site-oriented ease of use

The use of an alignment aid makes measurement easier for first-time users.In addition, the automatic adjustment of the light intensity eliminates

the need to replace the reference plate even for workpieces with significantly different reflectance.Furthermore, the analysis can be started using a non-contact sensor without touching the

mouse.

No concern about vibration caused by operations.

Please give us 35 seconds! This is a simple operation video!

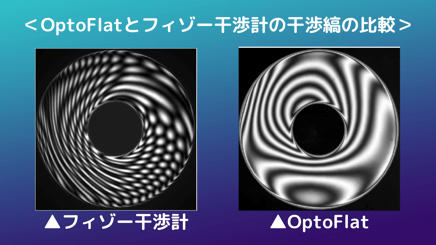

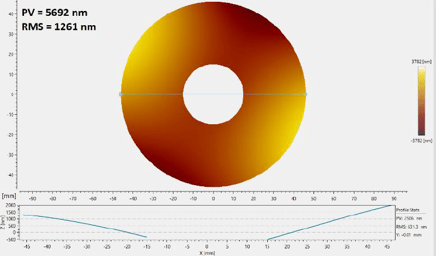

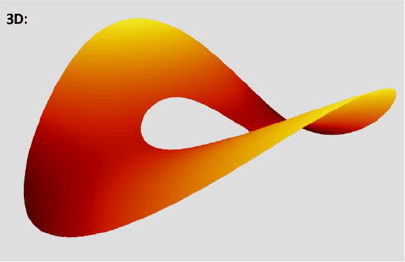

Reduction of backside reflection

In a laser interferometer, in the measurement of parallel plane samples,measurement is difficult due to the influence of the back surface reflection

wavefront on the front surface in some cases.On the other hand, in the low coherence interference principle, by limiting the coherence in a short region,Interference from the back surface can be

suppressed, and interference fringes from only the surface are generated.

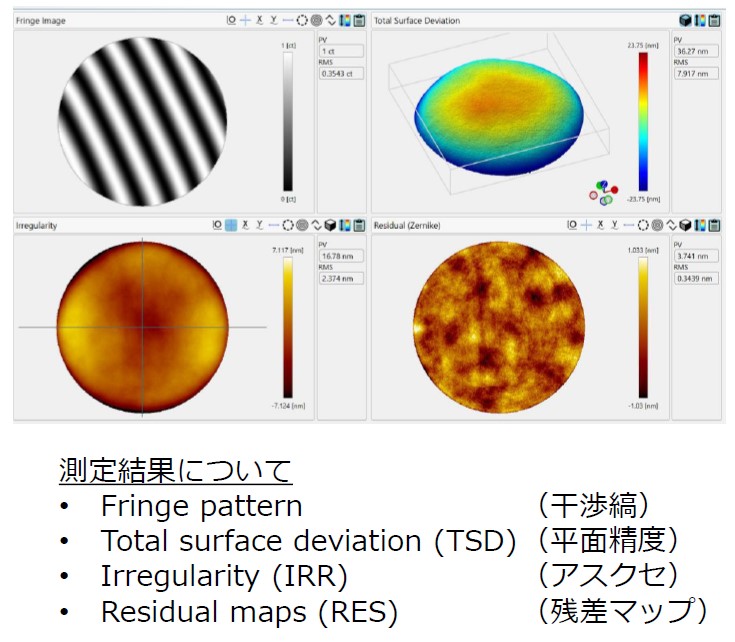

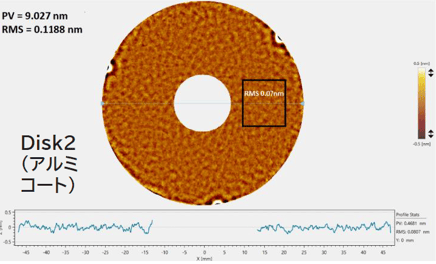

Measurement results example

Measurement results of flatness

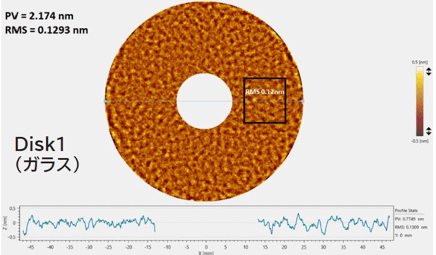

Measurement result of surface roughness

Main Specifications

●Analyzer and vibration isolation table are equipped as standard.

●Tool for measuring transmitted wavefront (option)

●Light source wavelength: 633.08nm

●Measurement accuracy: 1/20λ

●RMS accuracy (Short-term):0.1nm)

●RMS repeatability (Short-term):0.03nm)

●RMS accuracy (LONG-term):0.2nm)

●RMS repeatability (LONG-term):0.1nm)

●Resolution 1200x1200 Pixels(1x), 1920x1200 Pixels(4x)

●Measurement duration: < 1sec (single measurement)